Possess Sea Industrial Co., Ltd. - Derivatives Division

Professional Neoprene Materials & Products Manufacturer and Supplier in China

Professional Neoprene Materials & Products Manufacturer and Supplier in China

Contact: Ms.Maggie, Mobile / WhatsApp: +86 138 168 15888, E-mail: maggie@wetsuit.asia

Neoprene Socks, Wetsuit Socks, Wading Socks - Manufacturer

We use neoprene fabric (wetsuit fabric) to make foot socks, which provide warmth (cold water and wind chills), thermal insulation (hot sand) and protection (gravel damage) for both feet. They can be worn alone or with diving fins and water shoes combined for suitable for water and underwater sports and beach activities.

Professional neoprene socks are usually made with GBS (glue & blind stitch) because of the need for waterproofing. The outside seam line can be reinforced with "Tape" / "Liquid" / "Neotape". Use high-grade CR neoprene + super stretch fabric with 4-way stretchability material to ensure elasticity. The socks sole with dot non-slip printing or kevlar to improve strength and grip.

Neoprene Wetsuit / Wading Socks - 01

Material: SBR neoprene double laminated polyester fabric.

Thickness: 3mm (Provide other thickness).

Process: "Flatlock Stitch", seam construction lies flat and smooth against skin, durable, the sewing of contrasting lines shows the design sense perfectly. The thread residue is reinforced with "Bartack".

Sock Opening: Elastic band and hook and loop fasteners closure.

Sock Sole: Dot printing, non-slip texture, increase grip.

Features: Sock opening elastic band design, easy to put on and take off, minimizing water ingress.

Neoprene Wetsuit / Wading Socks - 02

Material: CR neoprene double laminated super stretch fabric.

Thickness: 3mm (Provide other thickness).

Process: "GBS", non-penetration stitching method after bonded with glue, prevent water from entering. The thread residue can be reinforced with "Glue" / "Spot Tape", the seam line can be reinforced with "Tape".

Sock Opening: Elastic Lycra cover.

Sock Sole: Dot printing, non-slip texture, increase grip.

Neoprene Wetsuit / Wading Socks - 03

Material: CR neoprene double laminated super stretch fabric.

Thickness: 3mm (Provide other thickness).

Process: "GBS", non-penetration stitching method after bonded with glue, prevent water from entering. The thread residue can be reinforced with "Glue" / "Spot Tape", the seam line can be reinforced with "Tape".

Sock Opening: Elastic Lycra cover.

Sock Sole: Kevlar, non-slip and wear-resistant / prevents injuries from sharp objects.

Features: Kevlar soles are used for added strength.

Neoprene Wetsuit / Wading Socks - 04

Material: CR neoprene double laminated super stretch fabric.

Thickness: 1.5mm (Provide other thickness).

Process: "Weld", Completely glued for better adhesion, stretch, water resistance and firmness. The seam line can be reinforced with "Neotape".

Sock Opening: Sock opening use smooth skin for close fit to prevent water from entering.

Sock Sole: Dot printing, non-slip texture, increase grip.

Features: Slim design, flexible and lightweight.

Neoprene Material Explain:

Normative Interpretation: "Neoprene" = "CR" ≠ "SCR" ≠ "SBR"

"Neoprene" just refers to the "CR" (Chloroprene Rubber), but now the industry "Neoprene" include "CR" (Chloroprene Rubber), "SCR" (Chloroprene & Styrene Butadiene Rubber), "SBR" (Styrene Butadiene Rubber).

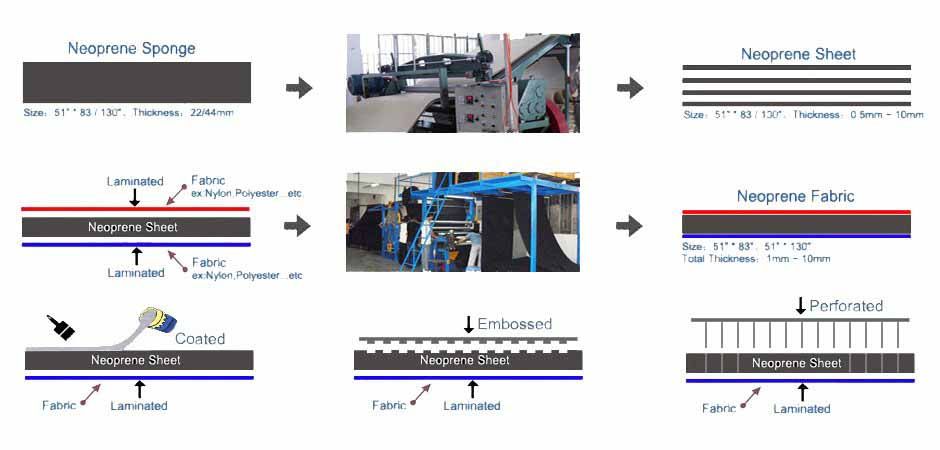

Normally we call the neoprene sponge as raw material, the product after cutting and laminated (cut thickness, laminated different fabric or coated / embossed / perforated) is called semi-finished product (neoprene fabric), the final product is called finished product (the product of neoprene material such as wetsuit, etc). We produce semi-finished product and finished products, semi-finished products (neoprene fabric) have a variety of uses, can be sold alone, the material Department of our factory has been supplying semi manufactured products (neoprene fabric) to manufacturing factories in various countries all over the world.

Neoprene sponge color is black, cream, aqua and white. Usually we use black, but if light color fabric is laminated, the use of cream, aqua or white neoprene sponge is better, this collocation can better reflect the color and bright of the light color fabric. If use the black neoprene sponge will light color fabric dark and distorted. But the cost of cream, aqua or white neoprene sponge is higher than the black neoprene sponge.

| Neoprene Type | CR | SCR | SBR |

| Sponge Color | Black, Cream | Black, Cream | Black, Cream, Aqua, White |

Neoprene Fabric Production Processing: